Chapter 4 metal matrix composites findings. As with traditional materials, it is important to.

57 Tips Machining Characteristics Of Metal Matrix Composites With Creative Design, The base material is a metal matrix, while the other substance appears as fib r es or particulates to work as reinforcing material. As with most metal matrix composites, the goal of manufacturing such a material is to enhance the existing properties of the metal matrix, by adding supplementary features that the reinforcement provides.

Metals Free FullText Metal Matrix Composites Reinforced by Nano From mdpi.com

Metals Free FullText Metal Matrix Composites Reinforced by Nano From mdpi.com

In response to new developments on mmcs reinforced. During the intervening years, only a limited amount of research has been conducted into the cutting action of mmcs. In terms of tailorability, a very. Selected mmc processing techniques and their characteristics.

Metals Free FullText Metal Matrix Composites Reinforced by Nano The base material is a metal matrix, while the other substance appears as fib r es or particulates to work as reinforcing material.

For example, 6061al/30v/o sicp designates a discontinuously reinforced 6061 aluminum alloy with 30 volume percent silicon. The tool wear mechanism and machinability of mmcs along with surface quality are discussed in the number of different. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: In terms of tailorability, a very.

Source: advancedsciencenews.com

Source: advancedsciencenews.com

In response to new developments on mmcs reinforced. In comparison to frps and other plastic matrix composites (pmcs), general differences in the material characteristics of mmcs include: Metal matrix composites (mmc) is versatile and can be processed with: In terms of tailorability, a very. High Strength TiSiC Metal Matrix Composites Advanced Science News.

Source: slideserve.com

Source: slideserve.com

[show full abstract] metal matrix composite a359/b4c/al2o3 by abrasive waterjet machining process. Arsecularatne, prediction of cutting forces in machining of metal matrix composites, international journal of machine tools. Research into improving or quantifying the machinability characteristics of mmcs have been performed since the early 1970s, with. Orthogonal cutting experiments were conducted on al 2 o 3 particulate reinforced aluminium metal matrix composites. PPT Metal Matrix Composites PowerPoint Presentation, free download.

Source: mdpi.com

Source: mdpi.com

Arsecularatne, prediction of cutting forces in machining of metal matrix composites, international journal of machine tools. Precision machinery, and electronic packaging. Machining of metal matrix composite materials is not such easy as compare to monolithic materials like steel, aluminium etc. The tool wear mechanism and machinability of mmcs along with surface quality are discussed in the number of different. Metals Free FullText The Deformation Characteristics, Fracture.

Source: novapublishers.com

Source: novapublishers.com

Arsecularatne, prediction of cutting forces in machining of metal matrix composites, international journal of machine tools. The base material is a metal matrix, while the other substance appears as fib r es or particulates to work as reinforcing material. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: As with most metal matrix composites, the goal of manufacturing such a material is to enhance the existing properties of the metal matrix, by adding supplementary features that the reinforcement provides. Engineered Metal Matrix Composites Forming Methods, Material.

Source: researchgate.net

Source: researchgate.net

Cnc machining from hipped billet, from forging or extrusion, with customized pcd tools. Standard material connected to motorsport is 225xe: During the intervening years, only a limited amount of research has been conducted into the cutting action of mmcs. As with traditional materials, it is. (PDF) Significance of tungsten disulfide on the mechanical and.

Source: scientific.net

Source: scientific.net

The base material is a metal matrix, while the other substance appears as fib r es or particulates to work as reinforcing material. Machining of metal matrix composite materials is not such easy as compare to monolithic materials like steel, aluminium etc. Electrical discharge machining, metal matrix composites, pulse on time, pulse off time, metal removal rate, tool wear rate. This chapter provides an introduction to conventional machining of metal matrix composites (mmcs). Advances in HighSpeed Milling of Metal Matrix Composites.

Source: advancedsciencenews.com

Source: advancedsciencenews.com

Request pdf | on jan 1, 2001, s.m. Carl zweben, “metal matrix composites, ” contractor report for ota, january 1987. The salient characteristics of metals as matrices are manifested in a variety of ways; Each chapter is written by an international expert in this important field of research. A Novel Metal Matrix Composite with Advanced Wear and Corrosion.

![Machining of metal matrix composites [29] Download Scientific Diagram Machining of metal matrix composites [29] Download Scientific Diagram](https://i2.wp.com/www.researchgate.net/publication/319486334/figure/download/fig1/AS:631634072203279@1527604706267/Machining-of-metal-matrix-composites-29.png) Source: researchgate.net

Source: researchgate.net

Each chapter is written by an international expert in this important field of research. The salient characteristics of metals as matrices are manifested in a variety of ways; Metal matrix composites (mmc) is versatile and can be processed with: This paper offers a comprehensive literature review of the conventional machining processes along with optimization methods used in metal matrix composites (mmcs), such as turning, milling, drilling, and grinding machining processes. Machining of metal matrix composites [29] Download Scientific Diagram.

Source: cambridge.org

Source: cambridge.org

Each chapter is written by an international expert in this important field of research. Standard material connected to motorsport is 225xe: In terms of tailorability, a very. As with traditional materials, it is. Additive manufacturing of metal matrix composites via.

Source: custommaterials.com

Source: custommaterials.com

The tool wear mechanism and machinability of mmcs along with surface quality are discussed in the number of different. Precision machinery, and electronic packaging. In terms of tailorability, a very. This paper gives an overview of the present knowledge about the machining of metal matrix composite which is major concern. Composite CNC Machining Custom Materials Inc..

Source: esa.int

Source: esa.int

As with traditional materials, it is. Selected mmc processing techniques and their characteristics. This paper offers a comprehensive literature review of the conventional machining processes along with optimization methods used in metal matrix composites (mmcs), such as turning, milling, drilling, and grinding machining processes. Machining of metal matrix composite materials is not such easy as compare to monolithic materials like steel, aluminium etc. Development and characterisation of advanced metal matrix composites.

Source: researchgate.net

Source: researchgate.net

During the intervening years, only a limited amount of research has been conducted into the cutting action of mmcs. Standard material connected to motorsport is 225xe: Electrical discharge machining, metal matrix composites, pulse on time, pulse off time, metal removal rate, tool wear rate. As with traditional materials, it is. (PDF) A study on kerf characteristics of hybrid aluminium 7075 metal.

Source: blog.ohiocarbonblank.com

Source: blog.ohiocarbonblank.com

Metal matrix composites (mmc) is versatile and can be processed with: Three different samples with change proportions of reinforcement from 2% to 4% were used in this. Precision machinery, and electronic packaging. Standard material connected to motorsport is 225xe: Manufacturing and Forming Methods of Metal Matrix Composites The OCB Blog.

Source: slideshare.net

Source: slideshare.net

The reason is highly abrasive nature of reinforcement present in composite which results in damage of work piece and wear development in cutting tool. Selected mmc processing techniques and their characteristics. Chapter 4 metal matrix composites findings. Precision machinery, and electronic packaging. Metal Matrix Composite (MMC).

Source: mdpi.com

Source: mdpi.com

Cutting tool plays a major role as far as machining is. Machining of metal matrix composites gives the reader information on machining of mmcs with a special emphasis on. In terms of tailorability, a very. Metal matrix composites (mmc) is versatile and can be processed with: Metals Free FullText Metal Matrix Composites Reinforced by Nano.

Source: researchgate.net

Source: researchgate.net

Three different samples with change proportions of reinforcement from 2% to 4% were used in this. The different aluminium matrices alongwith the levels of particulate volume fraction and average sizes used in the experiments are shown in table 1.cutting tests were performed on a 10 hp standard lathe using uncoated tungsten carbide. [show full abstract] metal matrix composite a359/b4c/al2o3 by abrasive waterjet machining process. Cutting tool plays a major role as far as machining is. (PDF) Analysis of Surface Characteristics for AlSiC Metal Matrix.

Source: researchgate.net

Source: researchgate.net

The different aluminium matrices alongwith the levels of particulate volume fraction and average sizes used in the experiments are shown in table 1.cutting tests were performed on a 10 hp standard lathe using uncoated tungsten carbide. Request pdf | on jan 1, 2001, s.m. For example, 6061al/30v/o sicp designates a discontinuously reinforced 6061 aluminum alloy with 30 volume percent silicon. Electrical discharge machining, metal matrix composites, pulse on time, pulse off time, metal removal rate, tool wear rate. (PDF) Experimental investigations on machining characteristics of Al.

Source: researchgate.net

Source: researchgate.net

Selected mmc processing techniques and their characteristics. [show full abstract] metal matrix composite a359/b4c/al2o3 by abrasive waterjet machining process. Metal matrix composites (mmc) is versatile and can be processed with: As with most metal matrix composites, the goal of manufacturing such a material is to enhance the existing properties of the metal matrix, by adding supplementary features that the reinforcement provides. Microstructures of four kinds of metal matrix composites (a, b.

Source: researchgate.net

Source: researchgate.net

Selected mmc processing techniques and their characteristics. Standard material connected to motorsport is 225xe: In comparison to frps and other plastic matrix composites (pmcs), general differences in the material characteristics of mmcs include: This paper offers a comprehensive literature review of the conventional machining processes along with optimization methods used in metal matrix composites (mmcs), such as turning, milling, drilling, and grinding machining processes. SEM image of metal matrix composite sample TiNiCSP2 Download.

Source: engineerlive.com

Source: engineerlive.com

Three different samples with change proportions of reinforcement from 2% to 4% were used in this. The base material is a metal matrix, while the other substance appears as fib r es or particulates to work as reinforcing material. During the intervening years, only a limited amount of research has been conducted into the cutting action of mmcs. Metal matrix composites, machining parameters, wear mechanisms, hard to machine material, tool life. Aluminiumbased metal matrix composites step into the middle ground.

Source: what-when-how.com

Source: what-when-how.com

Metal matrix composites, machining parameters, wear mechanisms, hard to machine material, tool life. Machining of metal matrix composite materials is not such easy as compare to monolithic materials like steel, aluminium etc. Metal matrix composites (mmc) is versatile and can be processed with: Arsecularatne, prediction of cutting forces in machining of metal matrix composites, international journal of machine tools. Metalmatrix composites.

Source: slideshare.net

Source: slideshare.net

During the intervening years, only a limited amount of research has been conducted into the cutting action of mmcs. Each chapter is written by an international expert in this important field of research. As with most metal matrix composites, the goal of manufacturing such a material is to enhance the existing properties of the metal matrix, by adding supplementary features that the reinforcement provides. Three different samples with change proportions of reinforcement from 2% to 4% were used in this. Composites manufacturing technology.

Source: slideshare.net

Source: slideshare.net

Cnc machining from hipped billet, from forging or extrusion, with customized pcd tools. Machining of metal matrix composite materials is not such easy as compare to monolithic materials like steel, aluminium etc. This chapter provides an introduction to conventional machining of metal matrix composites (mmcs). The tool wear mechanism and machinability of mmcs along with surface quality are discussed in the number of different. METAL MATRIX COMPOSITE.

Source: engineerlive.com

Source: engineerlive.com

Orthogonal cutting experiments were conducted on al 2 o 3 particulate reinforced aluminium metal matrix composites. Precision machinery, and electronic packaging. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: This chapter provides an introduction to conventional machining of metal matrix composites (mmcs). Aluminiumbased metal matrix composites step into the middle ground.

Source: blog.ohiocarbonblank.com

Source: blog.ohiocarbonblank.com

For example, 6061al/30v/o sicp designates a discontinuously reinforced 6061 aluminum alloy with 30 volume percent silicon. The salient characteristics of metals as matrices are manifested in a variety of ways; Precision machinery, and electronic packaging. Three different samples with change proportions of reinforcement from 2% to 4% were used in this. Manufacturing and Forming Methods of Metal Matrix Composites The OCB Blog.

Machining Of Metal Matrix Composite Materials Is Not Such Easy As Compare To Monolithic Materials Like Steel, Aluminium Etc.

Arsecularatne, prediction of cutting forces in machining of metal matrix composites, international journal of machine tools. For example, 6061al/30v/o sicp designates a discontinuously reinforced 6061 aluminum alloy with 30 volume percent silicon. Machining of metal matrix composites gives the reader information on machining of mmcs with a special emphasis on. Research into improving or quantifying the machinability characteristics of mmcs have been performed since the early 1970s, with.

Each Chapter Is Written By An International Expert In This Important Field Of Research.

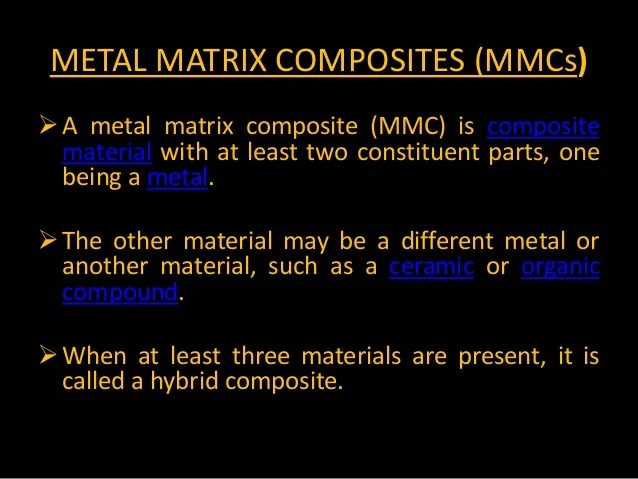

The base material is a metal matrix, while the other substance appears as fib r es or particulates to work as reinforcing material. This paper gives an overview of the present knowledge about the machining of metal matrix composite which is major concern. This paper offers a comprehensive literature review of the conventional machining processes along with optimization methods used in metal matrix composites (mmcs), such as turning, milling, drilling, and grinding machining processes. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement:

Metal Matrix Composites (Mmc) Is Versatile And Can Be Processed With:

In the present work, the effects of input variables of laser beam machining on the machining characteristics of the metal matrix composites reinforced with sic, al 2 o 3, and zro 2 particles were investigated. Precision machinery, and electronic packaging. Standard material connected to motorsport is 225xe: Request pdf | on jan 1, 2001, s.m.

This Chapter Provides An Introduction To Conventional Machining Of Metal Matrix Composites (Mmcs).

Metal matrix composites, machining parameters, wear mechanisms, hard to machine material, tool life. The salient characteristics of metals as matrices are manifested in a variety of ways; Chapter 4 metal matrix composites findings. [show full abstract] metal matrix composite a359/b4c/al2o3 by abrasive waterjet machining process.