Fibrous in nature within the other phase. The fabricated samples were subjected to optical microscope, scanning electron microscopy.

Step By Step Mechanical Characteristics Of Metal Matrix Composites With New Ideas, Aluminum, casting, metal matrix composites, tensile strength, impact strength, micro structure. Particle reinforced, short fiber or whickers reinforced, continuous fiber sheet reinforced metal matrix composite.

(PDF) Enhanced Mechanical Properties of Al6061 Metal Matrix Composites From researchgate.net

(PDF) Enhanced Mechanical Properties of Al6061 Metal Matrix Composites From researchgate.net

In this process, the reinforcement. This product has extensive applications in automotive, aerospace, and supplementary uses. And “titanium” denote alloysof these materials used as matrix metals. Senthil kumar a study on mechanical characteristics of hybrid metal matrix.

(PDF) Enhanced Mechanical Properties of Al6061 Metal Matrix Composites The 2014/ai2o3 composites exhibited softening at all cyclic plastic strain amplitudes and for different volume fractions of the discontinuous particulate reinforcement in the ductile metal matrix.

Weight percentage of cow dung ash and boron carbide were reinforced in ratios of 2.5:7.5, 5:5, and 7.5:2.5. Microstructural and mechanical characteristics of aa2014/sic surface composite fabricated by. Metal matrix composites (mmcs) because of their excellent properties such as light weight, higher ductility, higher strength etc. Metal matrix composites (mmcs) are used for structural, electrical, thermal, tribological and environmental applications.

Source: researchgate.net

Source: researchgate.net

Recently, dissimilar physical and chemical features of materials are. The focus of the selection of suitable process. Some mmc properties cannot be measured as they would be for monolithic metals. The properties of a deformation processed composite depend largely on the characteristics of the starting material, (PDF) Analysis of Mechanical Properties of Pure Aluminium Based Metal.

Source: what-when-how.com

Source: what-when-how.com

In this process, the reinforcement. The focus of the selection of suitable process. The composition of al2024 is given in table1 The fundamental design concept of composites is that the bulk phase accepts the load over a large Metalmatrix composites.

Source: pdfslide.net

Source: pdfslide.net

Metal matrix composites (mmcs) because of their excellent properties such as light weight, higher ductility, higher strength etc. The metal matrix is reinforced with the other material to improve strength and wear. For technology seekers it is very difficult to select appropriate techniques because there is lack of bench mark standards and industry experiences. Fibrous in nature within the other phase. Fabrication and Analysis of Mechanical Properties of Metal Matrix Nano.

Source: researchgate.net

Source: researchgate.net

Development of hybrid metal matrix composites has become an important area of research interest in material science. Metal matrix composite materials can be produced by many. Magnesium/hydroxyapatite composites were produced by conventional extrusion and their mechanical behavior studied under uniaxial compression at room temperature. Aluminum, casting, metal matrix composites, tensile strength, impact strength, micro structure. (PDF) Enhanced Mechanical Properties of Al6061 Metal Matrix Composites.

Development of hybrid metal matrix composites has become an important area of research interest in material science. The microstructure of few composites synthesized by this technique and the key and observable features are briefly highlighted considering the. In structural applications, the matrix is usually. Abstract— metal matrix composites are the most vital product used as engineering materials. Analysis of Mechanical Properties of Aluminium Based Metal Matrix.

Source: researchgate.net

Source: researchgate.net

Therefore the effects were studied by varying one parameter and keeping the other two as constant. Metal matrix composite materials can be produced by many different techniques. Are replacing conventional metallic materials in automobile and aerospace industries. Mechanical & machining characteristics of al/b4c metal matrix composites. (PDF) Material characterisation and mechanical properties of Al2O3Al.

Source: researchgate.net

Source: researchgate.net

Therefore the effects were studied by varying one parameter and keeping the other two as constant. The properties of a deformation processed composite depend largely on the characteristics of the starting material, Most metals and alloys make good matrices. Development of hybrid metal matrix composites has become an important area of research interest in material science. (PDF) Effect of Reinforcement Particle Size and Weight Fraction on the.

Source: semanticscholar.org

Source: semanticscholar.org

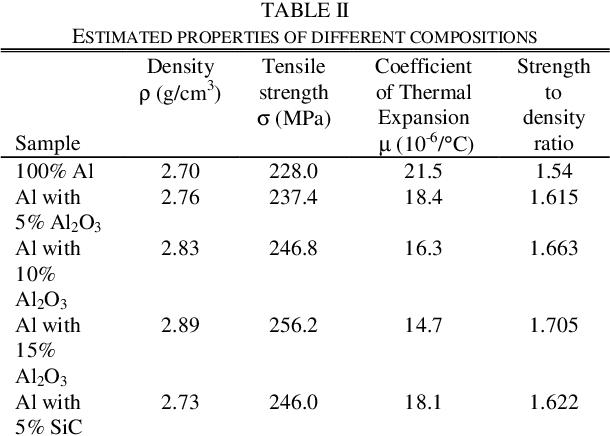

In structural applications, the matrix is usually. The properties of a deformation processed composite depend largely on the characteristics of the starting material, Senthil kumar a study on mechanical characteristics of hybrid metal matrix. Therefore the effects were studied by varying one parameter and keeping the other two as constant. Table II from Physiomechanical Properties of Aluminium Metal Matrix.

Source: researchgate.net

Source: researchgate.net

And “titanium” denote alloysof these materials used as matrix metals. [14], investigated the influence of metallic coating of reinforcements on the mechanical characteristics and Most metals and alloys make good matrices. Metal matrix composite materials can be produced by many different techniques. (PDF) Investigation on Mechanical, Tribological and Microstructural.

Source: google.com.au

Source: google.com.au

The microstructure of few composites synthesized by this technique and the key and observable features are briefly highlighted considering the. Fibrous in nature within the other phase. Stir casting or friction stir processing technique was used to fabricate the metal matrix composite. Mechanical & machining characteristics of al/b4c metal matrix composites. Patent WO2005068176A1 High impact strength, elastic, composite, fibre.

Source: degruyter.com

Source: degruyter.com

Metal matrix composites (mmc) consist of a metal and one or more other materials, typically a ceramic or organic compound. By contrast, mechanical properties of metal matrix composites are controlled by the matrix to a considerably larger extent, though fibers still provide the main contribution to strength and stiffness of the material. Most metals and alloys make good matrices. Some mmc properties cannot be measured as they would be for monolithic metals. Research review of diversified reinforcement on aluminum metal matrix.

Source: researchgate.net

Source: researchgate.net

Senthil kumar a study on mechanical characteristics of hybrid metal matrix. They also provide resistance to radiation and excellent electrical. A metal matrix composite is a type of metal that is reinforced with another material to improve strength, wear or some other characteristics. The properties of a deformation processed composite depend largely on the characteristics of the starting material, (PDF) Experimental Investigation on the Effect of Reinforcement.

Source: epfl.ch

Source: epfl.ch

Stir casting or friction stir processing technique was used to fabricate the metal matrix composite. The focus of the selection of suitable process. The properties of a deformation processed composite depend largely on the characteristics of the starting material, Mechanical & machining characteristics of al/b4c metal matrix composites. Mechanical properties of interfaces in metalmatrix composites ‒ GSM ‐ EPFL.

Source: researchgate.net

Source: researchgate.net

Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. Microstructural and mechanical characteristics of aa2014/sic surface composite fabricated by. The microstructure of few composites synthesized by this technique and the key and observable features are briefly highlighted considering the. The metal matrix is reinforced with the other material to improve strength and wear. (PDF) Physiomechanical properties of aluminium metal matrix composites.

Source: researchgate.net

Source: researchgate.net

Aluminum, casting, metal matrix composites, tensile strength, impact strength, micro structure. In this process, the reinforcement. Introduction aluminum is the familiar matrix for the metal matrix composites (mmcs) 1,2. The properties of a deformation processed composite depend largely on the characteristics of the starting material, (PDF) Performance of Mechanical Properties of Hybrid Aluminium Based.

Source: researchgate.net

Source: researchgate.net

Microstructural and mechanical characteristics of aa2014/sic surface composite fabricated by. Weight percentage of cow dung ash and boron carbide were reinforced in ratios of 2.5:7.5, 5:5, and 7.5:2.5. By contrast, mechanical properties of metal matrix composites are controlled by the matrix to a considerably larger extent, though fibers still provide the main contribution to strength and stiffness of the material. In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: (PDF) A Review on Mechanical and Thermal Properties of Aluminum Metal.

Source: mdpi.com

Source: mdpi.com

Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. Stir casting or friction stir processing technique was used to fabricate the metal matrix composite. Characterization and mechanical properties of al2024/sic metal matrix composites 107 2.1.materials used: Metal matrix composite materials can be produced by many different techniques. Materials Free FullText Improved Mechanical and Tribological.

Source: researchgate.net

Source: researchgate.net

Magnesium/hydroxyapatite composites were produced by conventional extrusion and their mechanical behavior studied under uniaxial compression at room temperature. They also provide resistance to radiation and excellent electrical. Fibrous in nature within the other phase. Development of hybrid metal matrix composites has become an important area of research interest in material science. (PDF) Mechanical properties of graphite/aluminum metal matrix composite.

Source: researchgate.net

Source: researchgate.net

Particle reinforced, short fiber or whickers reinforced, continuous fiber sheet reinforced metal matrix composite. And “titanium” denote alloysof these materials used as matrix metals. By contrast, mechanical properties of metal matrix composites are controlled by the matrix to a considerably larger extent, though fibers still provide the main contribution to strength and stiffness of the material. The fundamental design concept of composites is that the bulk phase accepts the load over a large (PDF) Enhancing the Mechanical Properties of Metal Matrix Composite by.

Source: scientific.net

Source: scientific.net

Most metals and alloys make good matrices. By contrast, mechanical properties of metal matrix composites are controlled by the matrix to a considerably larger extent, though fibers still provide the main contribution to strength and stiffness of the material. They also provide resistance to radiation and excellent electrical. Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. Study on Mechanical Properties of Al 7075 Hybrid Metal Matrix.

Source: slideserve.com

Source: slideserve.com

Some mmc properties cannot be measured as they would be for monolithic metals. Aluminum, casting, metal matrix composites, tensile strength, impact strength, micro structure. Microstructural and mechanical characteristics of aa2014/sic surface composite fabricated by. Fibrous in nature within the other phase. PPT Metal Matrix Composites PowerPoint Presentation ID4344148.

Source: researchgate.net

Source: researchgate.net

In materials science, a metal matrix composite (mmc) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel.the secondary phase is typically a ceramic (such as alumina or silicon carbide) or another metal (such as steel).they are typically classified according to the type of reinforcement: Particle reinforced, short fiber or whickers reinforced, continuous fiber sheet reinforced metal matrix composite. Characterization and mechanical properties of al2024/sic metal matrix composites 107 2.1.materials used: Property data given in this chapter are therefore given as ranges rather than as single values. (PDF) Investigation of Mechanical Properties of Aluminium Based Metal.

Source: researchgate.net

Source: researchgate.net

Are three kinds of metal matrix composite. Magnesium/hydroxyapatite composites were produced by conventional extrusion and their mechanical behavior studied under uniaxial compression at room temperature. Metal matrix composite materials can be produced by many. Stir casting or friction stir processing technique was used to fabricate the metal matrix composite. (PDF) Effects Of Porosity On Mechanical Properties Of Metal Matrix.

Source: researchgate.net

Source: researchgate.net

Stir casting or friction stir processing technique was used to fabricate the metal matrix composite. Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. The fabricated samples were subjected to optical microscope, scanning electron microscopy. Some mmc properties cannot be measured as they would be for monolithic metals. (PDF) An overview on mechanical properties of particulate reinforced.

Source: mdpi.com

Source: mdpi.com

Abstract— metal matrix composites are the most vital product used as engineering materials. Even though, various kinds of mmcs have been developed over the years, among them, aluminum (al) and magnesium (mg) mmcs. Therefore the effects were studied by varying one parameter and keeping the other two as constant. Some mmc properties cannot be measured as they would be for monolithic metals. Metals Free FullText An Overview of Metal Matrix.

Metal Matrix Composites (Mmc) Consist Of A Metal And One Or More Other Materials, Typically A Ceramic Or Organic Compound.

Particle reinforced, short fiber or whickers reinforced, continuous fiber sheet reinforced metal matrix composite. Metal matrix composites (mmcs) because of their excellent properties such as light weight, higher ductility, higher strength etc. The composition of al2024 is given in table1 In structural applications, the matrix is usually.

For Technology Seekers It Is Very Difficult To Select Appropriate Techniques Because There Is Lack Of Bench Mark Standards And Industry Experiences.

Introduction aluminum is the familiar matrix for the metal matrix composites (mmcs) 1,2. Recently, dissimilar physical and chemical features of materials are. The microstructure of few composites synthesized by this technique and the key and observable features are briefly highlighted considering the. Metal matrix composites (mmcs) are used for structural, electrical, thermal, tribological and environmental applications.

Therefore The Effects Were Studied By Varying One Parameter And Keeping The Other Two As Constant.

Some mmc properties cannot be measured as they would be for monolithic metals. Senthil kumar a study on mechanical characteristics of hybrid metal matrix. Abstract— metal matrix composites are the most vital product used as engineering materials. The 2014/ai2o3 composites exhibited softening at all cyclic plastic strain amplitudes and for different volume fractions of the discontinuous particulate reinforcement in the ductile metal matrix.

Metal Matrix Composite Materials Can Be Produced By Many Different Techniques.

Magnesium/hydroxyapatite composites were produced by conventional extrusion and their mechanical behavior studied under uniaxial compression at room temperature. Aluminum based metal matrix composites have good specific modulus, strength, wear and fatigue characteristics so that these composites play very significant role in the field automobile, aerospace, chemical and. Development of hybrid metal matrix composites has become an important area of research interest in material science. A metal matrix composite is a type of metal that is reinforced with another material to improve strength, wear or some other characteristics.