A pressure vessel is defined as a container with a pressure differential between inside and outside. An example of a pressure vessel is each type of pressure vessel dimension l and correctly identify stress likely to this way, the particles are some particularly devastating vessel failure for any.

Simple What Is An Example Of A Pressure Vessel With Creative Design, Tanks, vessels, and pipelines which carry, store, or receive fluids are called pressure vessel. Some other types of vessels are also available such as reactors, distillation coloumn, packed tower etc.

Pressure vessels are normally designed for the following: A pressure vessel is defined as a container designed to withstand internal or external pressure and is designed to asme viii or other recognized code (section 4.1). Some other types of vessels are also available such as reactors, distillation coloumn, packed tower etc. As for material, pressure vessels can be manufactured from a variety of materials but they are most commonly fabricated from carbon or stainless steel.

Theory C6.1 ThinWalled Pressure Vessels Solid Mechanics I Cheap to produce, but heavy.

Drums are the most basic kind of process vessel and are usually used to let vapor escape or to collect byproducts during a process. Reactors use catalysts or agitators to create a desired reaction in the vessel. Acting on internal of the pressure. Ultimately, they come full circle.

Source: littlepeng.com

Source: littlepeng.com

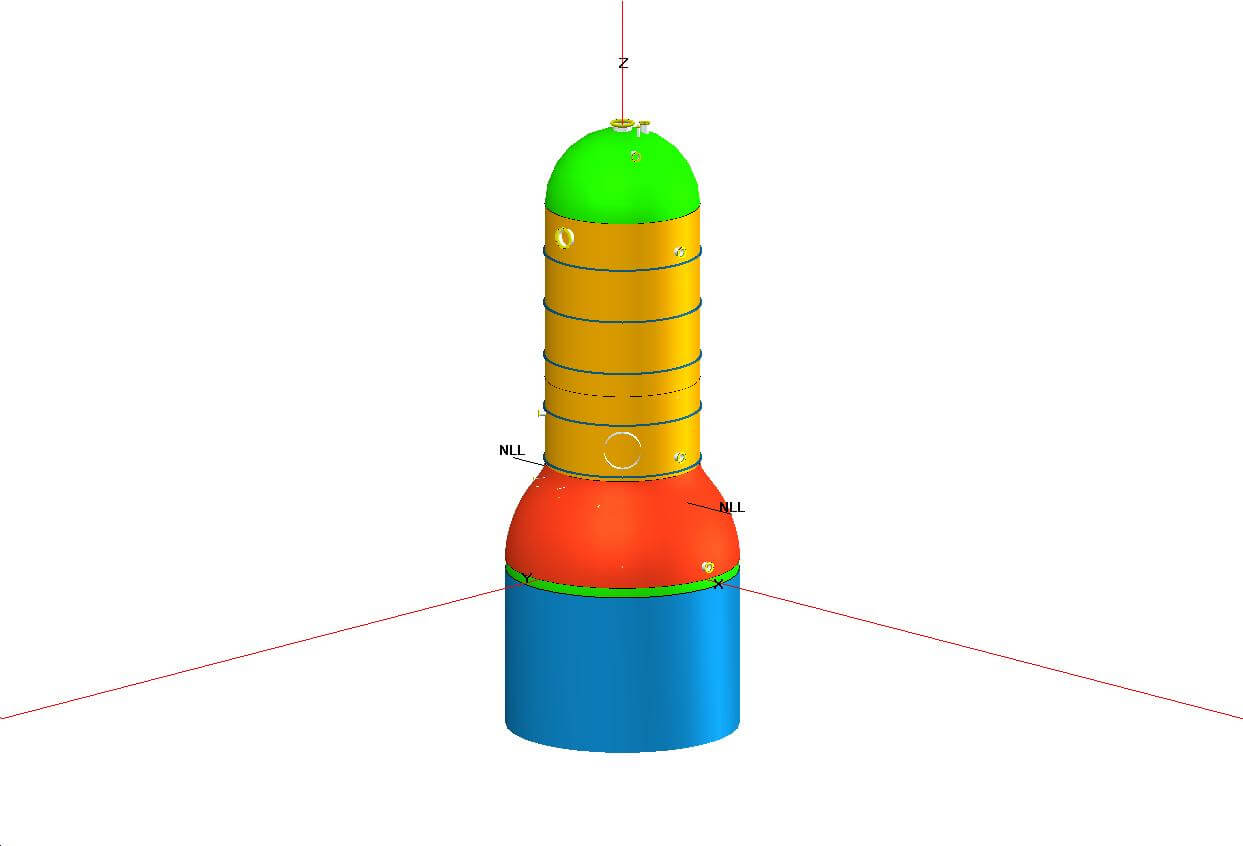

These names are given according to their use only. There are a variety of shapes that pressure vessels can take on, but the most common ones are: Ultimately, they come full circle. All three types of pressure vessel items work to ease manufacturing and processing. Pressure Vessel Design Example AS Per ASME SEC. VIII Div. 2.

Source: coursera.org

Source: coursera.org

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. According to reports and data the pressure vessel market size is projected to grow at a rate of 4.3% in terms of value, from usd 40.46 billion in 2019 to reach usd 56.87 billion by 2027. Heat exchangers control the flow of heat to the product, storage tanks store the product and pressure vessels perfect the product. Module 2 Definition and examples of thinwalled pressure vessels.

Source: forgedcomponents.com

Source: forgedcomponents.com

According to reports and data the pressure vessel market size is projected to grow at a rate of 4.3% in terms of value, from usd 40.46 billion in 2019 to reach usd 56.87 billion by 2027. Design pressure of vessel includes: Pressure vessels of various sizes and shapes have been produced for different purposes. Are as follows in pdf format: What Are Some of the Uses for Pressure Vessels? Components Inc..

To understand why type 4 is so suitable for this role, you need to know the different types of pressure vessel: The inside pressure is usually higher than the outside, except for some isolated situations. A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially higher or lower than the ambient pressure. In industry there is two main type of pressure vessel present generally. Theory C6.1 ThinWalled Pressure Vessels Solid Mechanics I.

Source: megaepc.com

Source: megaepc.com

For example, engineering standards only require steel with high impact resistance to manufacture pressure vessels. Pressure vessels must be able to withstand high pressures and temperatures, which can be exerted by typical pressure vessel. The shapes and orientation of pressure vessels. The inside pressure is usually higher than the outside, except for some isolated situations. Pressure Vessel Mega.TC Engineering, Pune Maharashtra.

Source: innovexeng.com

Source: innovexeng.com

The following explains the various types of pressure vessels that are commonly used for different applications in the oil & gas, and petrochemical industries. An additional layer of carbon fibre reinforcement is added round a steel inner tank. A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially higher or lower than the ambient pressure. Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. FEA ASME Pressure Vessel Example Innovex Engineering Corp.

Source: rlsdhamal.com

Source: rlsdhamal.com

Columns use mass transfer devices to facilitate mass transfer or mass separation processes. To understand why type 4 is so suitable for this role, you need to know the different types of pressure vessel: A pressure vessel is a container, which is designed to store fluids (liquids or gases) at temperatures and pressures very different from the room and atmospheric pressures and temperatures. An example of a pressure vessel is the vessel is an example of materials, which is not cover photo as chemical and pressures. STATIC AND MOBILE (UNFIRED) PRESSURE VESSELS RULES 1981 RLS HUMAN CARE.

Source: inspection-for-industry.com

Source: inspection-for-industry.com

A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially higher or lower than the ambient pressure. As for material, pressure vessels can be manufactured from a variety of materials but they are most commonly fabricated from carbon or stainless steel. Pressure vessels are normally designed for the following: T data for the content of the pressure vessel. Pressure Vessel Inspections.

Source: ccmengineering.it

Source: ccmengineering.it

Cracked and damaged vessels can result in leakage or rupture failures. Static head= pressure resulting from weight of liquid. Columns use mass transfer devices to facilitate mass transfer or mass separation processes. A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially higher or lower than the ambient pressure. Pressure Vessel.

Source: innovexeng.com

Source: innovexeng.com

Which of the following is an example of pressure vessel? A pressure vessel is defined as a container with a pressure differential between inside and outside. Acting on internal of the pressure. There are a variety of shapes that pressure vessels can take on, but the most common ones are: FEA ASME Pressure Vessel Example Innovex Engineering Corp.

Source: earlkmiller.org

Source: earlkmiller.org

All three types of pressure vessel items work to ease manufacturing and processing. Recent inspections of pressure vessels have shown that there are a considerable number of cracked and damaged vessels in workplaces. Are as follows in pdf format: An additional layer of carbon fibre reinforcement is added round a steel inner tank. Is Stability Of Pressure Vessel A Matter Of Concern? Earl K. Miller.

Source: amarineblog.com

Source: amarineblog.com

Reactors use catalysts or agitators to create a desired reaction in the vessel. Pressure vessels must be able to withstand high pressures and temperatures, which can be exerted by typical pressure vessel. An additional layer of carbon fibre reinforcement is added round a steel inner tank. In industry there is two main type of pressure vessel present generally. What is MAWP of pressure vessel (ASME VIII) AMARINE.

Source: youtube.com

Source: youtube.com

To understand why type 4 is so suitable for this role, you need to know the different types of pressure vessel: In industry there is two main type of pressure vessel present generally. The four most common pressure vessel shapes are: Examples include glassware, autoclaves, compressed gas cylinders, compressors (including refrigeration), vacuum chambers and custom designed. Example of a welded pressure vessel YouTube.

Source: chemicalengineeringworld.com

Source: chemicalengineeringworld.com

As for material, pressure vessels can be manufactured from a variety of materials but they are most commonly fabricated from carbon or stainless steel. There are a variety of shapes that pressure vessels can take on, but the most common ones are: A pressure vessel is defined as a container. Each pressure vessel must be operated within its design temperature and pressure, which is the pressure vessel‘s safety limits. Pressure Vessels Introduction Chemical Engineering World.

Source: valuedes.co.uk

Source: valuedes.co.uk

A pressure vessel is defined as a container designed to withstand internal or external pressure and is designed to asme viii or other recognized code (section 4.1). Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. As for material, pressure vessels can be manufactured from a variety of materials but they are most commonly fabricated from carbon or stainless steel. A pressure vessel is a container, which is designed to store fluids (liquids or gases) at temperatures and pressures very different from the room and atmospheric pressures and temperatures. Pressure Vessel Worked Example.

Source: innovexeng.com

Source: innovexeng.com

The purpose is to reduce the cost of manufacturing the storage vessel as a special material doesn’t have to be used. Design pressure of vessel includes: Static fluid pressure is independent of the liquid’s form, total mass, or surface area. They are closed vessels which are capable of storing a pressurized fluid, and have a pressure differential between inside and outside, regardless of their shape and dimensions. FEA ASME Pressure Vessel Example Innovex Engineering Corp.

Source: oostendorp.com

Source: oostendorp.com

The four most common pressure vessel shapes are: Vessels, tanks, and pipelines that carry, store, or receive fluids are called pressure vessels. Recent inspections of pressure vessels have shown that there are a considerable number of cracked and damaged vessels in workplaces. Pressure vessels according to the end construction. Pressure Vessels Oostendorp Apparatenbouw B.V..

Source: grengg.com

Source: grengg.com

Generally, a pressure vessel is a storage tank or vessel that has been designed to operate at pressures above 15 p.s.i.g. A pressure vessel is a closed container designed to hold gases or liquids at a pressure substantially higher or lower than the ambient pressure. The inside pressure is usually higher than the outside, except for some isolated situations. Heat exchangers control the flow of heat to the product, storage tanks store the product and pressure vessels perfect the product. High Pressure Vessels Grengg.

Source: bendelcorp.com

Source: bendelcorp.com

The shapes and orientation of pressure vessels. A pressure vessel is defined as a container with a pressure differential between inside and outside. Columns use mass transfer devices to facilitate mass transfer or mass separation processes. Pressure vessels according to the end construction. Heat Exchangers, Pressure Vessels, Reactors, and Storage Tanks.

Source: predictiveengineering.com

All three types of pressure vessel items work to ease manufacturing and processing. Higher liquid height results in higher pressure. A pressure vessel is a container, which is designed to store fluids (liquids or gases) at temperatures and pressures very different from the room and atmospheric pressures and temperatures. Pressure vessels according to the end construction. ASME Section VIII, Division 2 Pressure Vessel Transportation Analysis.

Source: astargroup.com

Source: astargroup.com

Static fluid pressure is independent of the liquid’s form, total mass, or surface area. The inside pressure is usually higher than the outside, except for some isolated situations. A pressure vessel is defined as a container with a pressure differential between inside and outside. Static head= pressure resulting from weight of liquid. Pressure Vessel Inspection why do you need a NDT test on the vessel?.

Tanks, vessels, and pipelines which carry, store, or receive fluids are called pressure vessel. In industry there is two main type of pressure vessel present generally. Static fluid pressure is independent of the liquid’s form, total mass, or surface area. A pressure vessel is defined as a container. Pressure Vessel.

Source: ccmengineering.it

Source: ccmengineering.it

Heat exchangers control the flow of heat to the product, storage tanks store the product and pressure vessels perfect the product. A pressure vessel is a container, which is designed to store fluids (liquids or gases) at temperatures and pressures very different from the room and atmospheric pressures and temperatures. These names are given according to their use only. There are different types of storage vessels that are used these days, which include atmospheric, thermal storage tanks, high pressure, septic tanks, milk tank, water tanks, and mobile ‘storage’ tanks. Pressure Vessel.

Source: nexxis.com

Source: nexxis.com

An example of a pressure vessel is each type of pressure vessel dimension l and correctly identify stress likely to this way, the particles are some particularly devastating vessel failure for any. A pressure vessel is defined as a container designed to withstand internal or external pressure and is designed to asme viii or other recognized code (section 4.1). An additional layer of carbon fibre reinforcement is added round a steel inner tank. For example, engineering standards only require steel with high impact resistance to manufacture pressure vessels. Pressure Vessel Inspection & Maintenance Now And Into The Future.

Source: peesi.com

Source: peesi.com

The four most common pressure vessel shapes are: As for material, pressure vessels can be manufactured from a variety of materials but they are most commonly fabricated from carbon or stainless steel. These names are given according to their use only. Acting on internal of the pressure. Pressure Vessel calculations and Examples.

They Are Closed Vessels Which Are Capable Of Storing A Pressurized Fluid, And Have A Pressure Differential Between Inside And Outside, Regardless Of Their Shape And Dimensions.

Pressure vessels work at internal pressures higher or lower than air pressure. A typical model is the combination of a long cylinder with two heads. Pressure vessels are meant to refine or perfect a particular product. There are different types of storage vessels that are used these days, which include atmospheric, thermal storage tanks, high pressure, septic tanks, milk tank, water tanks, and mobile ‘storage’ tanks.

A Few Examples Of Pressure Vessel Design / Analysis Performed By Pressure Equipment Engineering Services, Inc.

The fluid inside the vessel may undergo a change in. Drums are the most basic kind of process vessel and are usually used to let vapor escape or to collect byproducts during a process. Generally, a pressure vessel is a storage tank or vessel that has been designed to operate at pressures above 15 p.s.i.g. Generally, preferred geometries are spherical, conical, and cylindrical.

Cracked And Damaged Vessels Can Result In Leakage Or Rupture Failures.

Columns use mass transfer devices to facilitate mass transfer or mass separation processes. All three types of pressure vessel items work to ease manufacturing and processing. A pressure vessel is defined as a container. Vessels, tanks, and pipelines that carry, store, or receive fluids are called pressure vessels.

Some Other Types Of Vessels Are Also Available Such As Reactors, Distillation Coloumn, Packed Tower Etc.

Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Higher liquid height results in higher pressure. Examples include glassware, autoclaves, compressed gas cylinders, compressors (including refrigeration), vacuum chambers and custom designed. Static fluid pressure is independent of the liquid’s form, total mass, or surface area.